Canadian ship owners invest in greener vessels

InnovationCanada’s leading ship owners invest significantly in fleet renewal to maximize efficiencies

The financial challenges facing ship owners in terms of fleet upkeep and renewal differ in Canada and the United States as a result of regulations. Fleet renewal in Canada has been robust ever since the federal government repealed a 25% tariff in 2010 that has since allowed foreign-built ships to be purchased duty free for domestic use, making their costs more feasible than in North America. The leading Canadian ship owners – all participants in Green Marine – have responded with steady orders of new-builds, assessing each one carefully with an eye to further improving the efficiencies and, in some cases, technologies of the next. Here’s what Algoma Central Corporation, Canada Steamship Lines, Fednav, and Groupe Desgagnés have been doing.

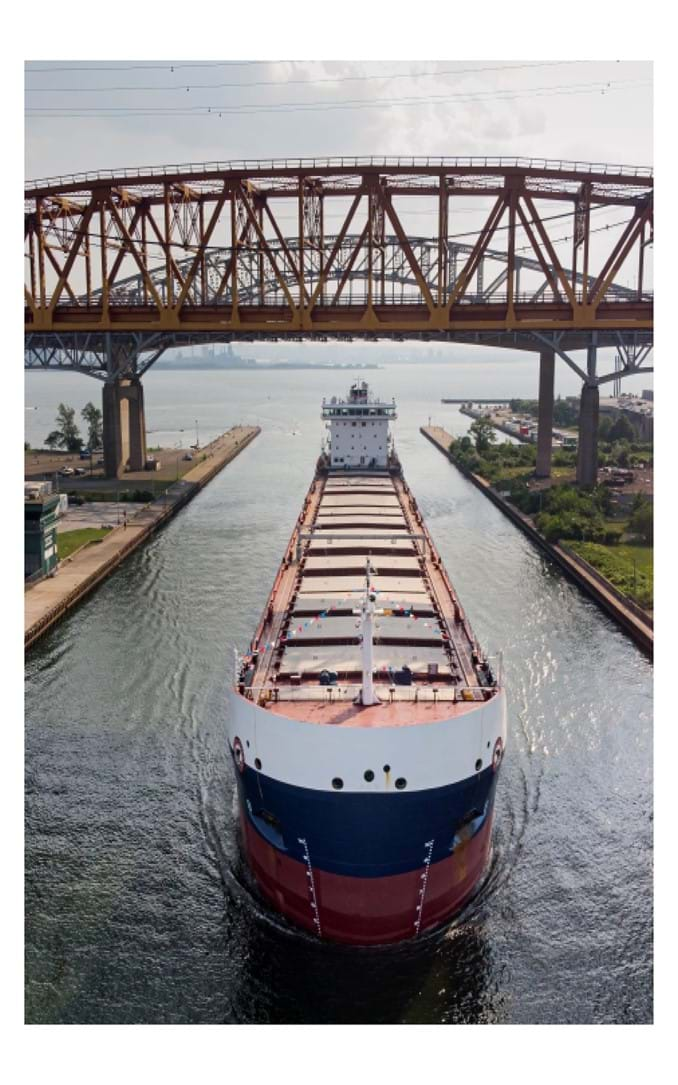

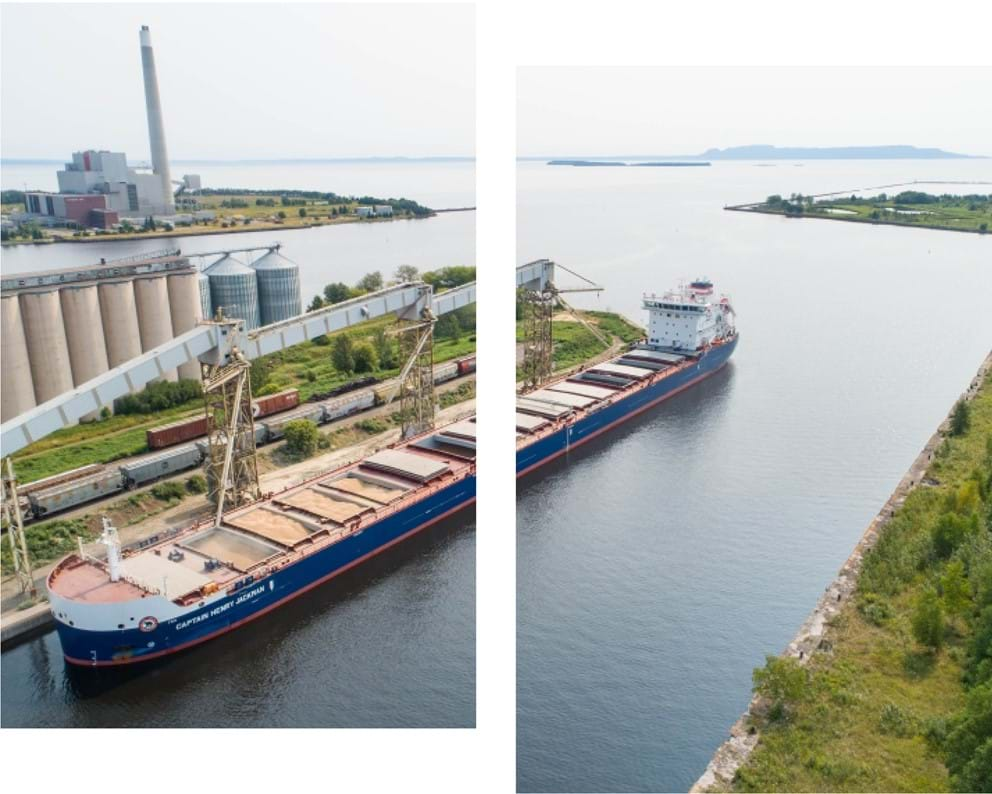

Algoma Central Corporation

Algoma Central Corporation has focused on building a more sustainable domestic dry-bulk fleet over the past decade, starting with the delivery of its first Equinox Class ship in 2013. Nine additional Equinox Class vessels have since been entered into operation.

We currently have two Equinox Class vessels under construction, the Algoma Bear and the Algoma Endeavour, both of which are expected to arrive in 2024.

Since Algoma began to conceptualize the Equinox Class in 2010, the company has continually improved on the original design’s efficiencies to the point where the newest version has been coined the Equinox Class 3.0. “In 2021, the Captain Henry Jackman, which is the 10th in this class and the first incorporating the 3.0 design, has greater cargo deadweight capacity, lighter aluminum hatch covers, an improved twin rudder design,” Wright says.

The Captain Henry Jackman will also have FuelOpt technology installed next year to optimize propulsion. Algoma first tried out the FuelOpt system aboard the Algoma Conveyor in 2021. “By automatically and dynamically monitoring and controlling the vessel’s propulsion power in real time, FuelOpt provided a 10% reduction in fuel consumption while the vessel was operating at full-away speed,” Wright notes.

Algoma has since installed FuelOpt on nine of its Equinox Class vessels and plans to do so on the Captain Henry Jackman in 2023, with additional installations being considered.

“In July, we set new targets to reduce our greenhouse gas emissions by 40% by 2030 compared to the 2008 baseline and to achieve net-zero emissions by 2050 across all of our business units,” Wright adds.

Reaching net zero will require collaboration with many partners.

All the Equinox Class ships are equipped with a closed-loop exhaust gas cleaning system. “The testing we did on the Algoma Equinox in 2017 demonstrated a 98.3% removal of SOx, 43% removal of total suspended particulate matter, and a 7% NOx removal,” Wright says. “Other studies also show that scrubbers remove anywhere from 20 to 50% of black carbon, all proving this to be an effective technology to meet the SOx requirements in Emission Control Areas, as well as to reduce other air emissions.”

Since 2018, Algoma has been working closely with Beaverlabs Software Inc., a Green Marine partner, on integrating customized vessel performance monitoring software. “The Prism analytics tool we acquired facilitates analyzing a wide range of vessel and machinery performance metrics, and to compare that performance with past voyage data and current vessels,” Wright explains.

The company assembled an internal team in 2021 to explore, in collaboration with key stakeholders, further new ways to decarbonize the fleet. “This working group continues to research evolving technology and innovation and is currently looking at trialing biofuel on a vessel next year,” Wright shares.

Other efforts to enhance vessel sustainability include participating in a research project with Transport Canada to quantify the impact of hull coatings on vessel efficiency in the Great Lakes and St. Lawrence Seaway routes.

Photos: Algoma Central Corporation

______________

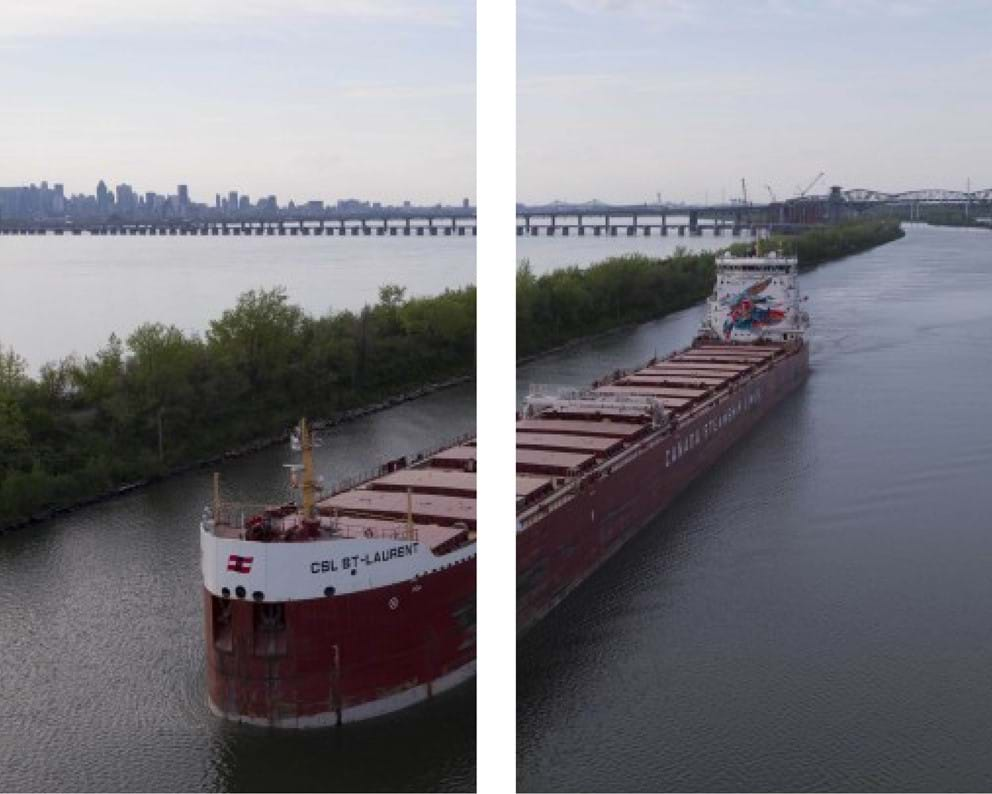

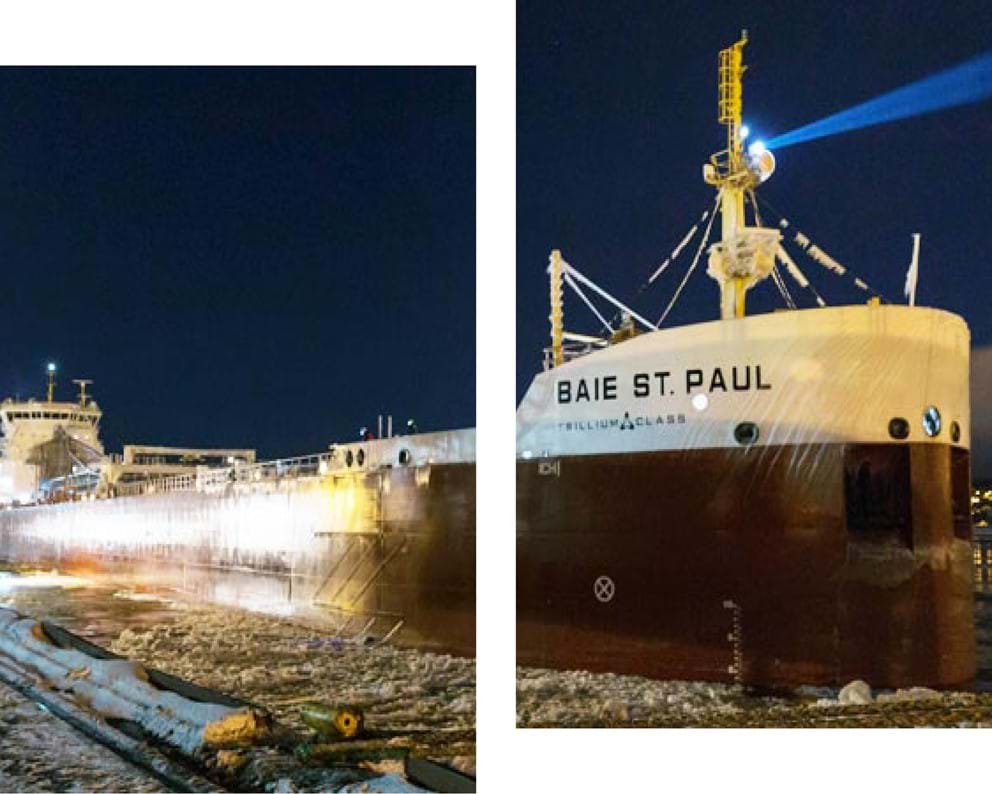

Canada Steamship Lines

Over the last decade, Canada Steamship Lines (CSL) has significantly invested in fleet renewal on the Great Lakes, starting with the introduction of its Trillium Class vessels between 2012 and 2014. Its newest vessel, the MV Nukumi, is the first diesel-electric laker and single-point loader to operate in Canada.

As a result of its modern and efficient fleet, CSL reduced its greenhouse gas (GHG) emissions by 26% as of 2021.

This achievement represents 86% of our 2030 goal to emit 35% less CO2 equivalent per tonne of cargo moved, compared to 2005.

“Our annual total GHG emissions reduction rate per tonne-nautical mile is now 2.6%, which is on target to meet the International Maritime Organization’s decarbonization goal to cut emissions by at least half by 2050 compared to 2008 levels,” Sykora adds.

The six Trillium Class vessels operating on the Great Lakes and three working internationally feature highly efficient Tier 3 engines, along with an electronically controlled main engine and onboard fuel monitoring system to maximize efficiencies. A Trillium class ship can transport one tonne of cargo a distance of 558 kilometres with one litre of fuel (compared to rail going 224 km and a truck’s distance being 49 km).

Making its debut voyage last January 31st, the Nukumi features diesel-electric Tier 3 engines, a ballast water treatment system, and waste heat recovery system.

“This vessel emits approximately 25% less GHG emission and 80% less harmful air pollutants compared to the previous vessel servicing the same salt routes,” Sykora says. “The quieter machinery also helps to protect marine ecosystems, and endangered species such as the North Atlantic right whale, from underwater noise.”

Over the last three years, CSL ships have furthermore accumulated more than 30,000 running hours in a biodiesel initiative, which is the world’s longest such trials. “We’ve managed to attain lifecycle reductions of carbon dioxide emissions of 80% when compared to marine gas oil use,” Sykora says.

As a result of these trials, we’ve prevented 43,000 metric tons of carbon emissions from entering the atmosphere, which is equivalent to removing 9,300 passenger vehicles off the road annually.

“CSL is continuing to work toward decarbonizing operations by expanding the use of biodiesel across our fleet, conducting a shore power feasibility in Canada, as we already have one under way in Australia, and continuing to leverage or advanced O2 System and digital data to maximize the energy efficiency of our ships,” Sykora says.

Photos: Canada Steamship Lines

______________

Fednav

Fednav embarked on a major fleet rejuvenation program in 2015, taking delivery of 25 highly efficient new-builds from Japanese shipyards over the next six years. “We followed that up two years ago with an order for 10 additional vessels,” says Martin Krafft, Fednav’s Vice President, Fleet Management.

As a result of this continual investment in fleet renewal, Fednav has reduced its emissions by 22% as of 2021 and is on target to achieve the IMO’s 50% carbon emission reduction goal by 2050.

Fednav’s entire fleet is equipped with and uses voyage optimization software for every trip.

There’s significant potential in optimizing the speed profile of each vessel which in turn has a positive impact on fuel consumption and the related emissions.

An in-house team of naval architects continuously works with shipyards and other external partners to further optimize the vessel hydrodynamics and onboard energy consumption of its ships. “And we’re constantly working to reduce our footprint by investing in the most advanced and fuel-efficient options available for our fleet,” Krafft adds.

Photos: Fednav

______________

Groupe Desgagnés

Groupe Desgagnés has significantly reduced its environmental footprint by investing in new tankers that can use liquid natural gas (LNG) whenever possible to reduce its fleet’s environmental footprint to a level unparalleled in Canada.

“These vessels can provide a 20% to 35% reduction in GHG emissions when the LNG option, low-design methane slips, and energy efficiency improvements are all in operation,” says Daniel Côté, Senior Environmental Advisor at Transport Desgagnés.

All four of the company’s new-generation product tankers have each been custom-built according to an original concept developed by Groupe Desgagnés. The design optimizes voyaging safety, operational efficiency and environmental performance, along with equipping the vessels for the often harsher navigational conditions of Northern Quebec and the Great Lakes with Polar 7 certification.

Costing upwards of $200 million in total, the four new tankers were all constructed at the Besiktas shipyard in Yalova, near Istanbul, Turkey. “Each of these vessels is the result of multiple innovations,” Côté adds.

They each tangibly reflect the Desgagnés vision and leadership in providing safe, environmentally friendlier, sustainable transportation for refined petroleum or other chemical products.

Photos: Groupe Desgagnés

___________________

READ MORE ON THIS TOPIC:

Interlake sets optimistic course with first new U.S. Great Lakes vessel in four decades