Interlake's new Great Lakes freighter — A 1st in 40 years

InnovationInterlake sets optimistic course with first new U.S. Great Lakes vessel in four decades

Over the past 15 years, Green Marine’s participating ship owners have significantly invested in upgrading the environmental performance of their fleets by replacing older vessels with new-builds and/or retrofitting existing vessels with new, cleaner running engines and innovative technologies to maximize fuel efficiencies and minimize air-polluting emissions. In the United States, the emphasis has been on upgrading vessels. The fresh water of the Great Lakes and St. Lawrence is kinder to the longevity of ships than sea water tends to be, making it easier to keep ships in service longer. The great news is that a strong long-term commitment with a loyal customer has made the U.S. construction of brand-new ship feasible for a leading American ship owner, and Green Marine participant, on the Great Lakes.

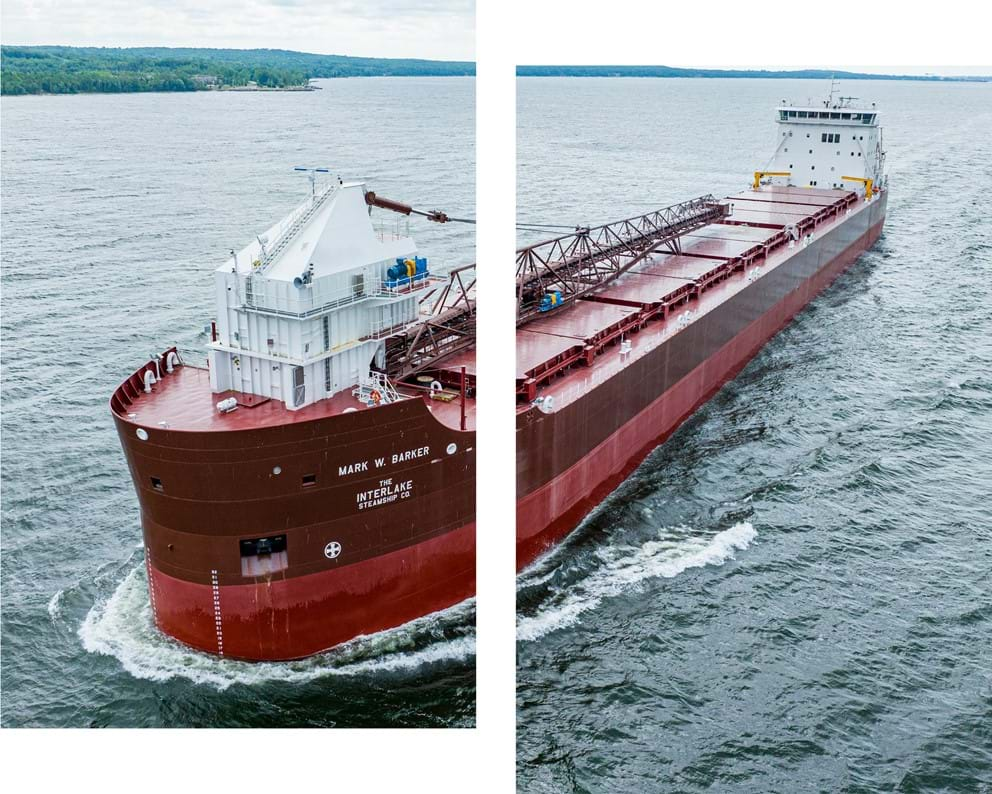

The Interlake Steamship Company has introduced the first newly constructed ship in the U.S. Great Lakes region in nearly 40 years. The Mark W. Barker bulk carrier was officially christened in Cleveland at the end of August, but the vessel had already been moving cargo for over a month.

“We’re so proud to have this new Made in the U.S.A. vessel built under fair American labour regulations and wages with domestically mined iron ore that was turned into the U.S. steel we needed,” says Mark W. Barker, Interlake’s President and the second-generation leader of the family-owned and -operated company.

Barker is humbled to have the vessel named after him.

It’s hard to say no when your father, who is also the chairman of your company, insists on this, but I won’t lie: it’s a real honour!

Constructed at Fincantieri Bay Shipbuilding in Sturgeon Bay, Wisconsin, the 639-foot (almost 195-metre) vessel can transport various types of cargo through the freshwater Great Lakes and river systems.

“Our primary contract with Cargill to deliver road salt, along with other new cargo opportunities, prompted us to start making this huge commitment five years ago to add a new vessel to our fleet,” Barker says. “We determined that a new vessel would best meet customer needs and it has already carried aggregates, limestone, iron ore, sand, as well as steel, ahead of transporting road salt for this winter.”

Innovative design

The Mark W. Barker distinguishes itself from most Great Lakes freighters with a cargo hold that has more of a square and flat shape instead of a traditional sloped hull. A forward mounted self-unloading boom gives customers greater versatility in terms of where their cargo is unloaded at ports. A single-hold belt leads to a forward loop-belt system that feeds the deck-mounted boom.

Our hull design offers greater flexibility in terms of the kinds of cargo we can transport in the middle of the hold.

“The five large hydraulically controlled and stackable hatches make it easier for cranes to move huge cargo in and out of the hold,” Barker adds.

A shorter length, along with precise steering equipment, make it easier to navigate the sharp turns and narrow passages of the Cuyahoga River near and through Cleveland, Ohio. The boxier design facilitates carrying 26,000 U.S. ton of cargo with the unloading process fully automated.

Tier 4 engines

Barker says Interlake is excited to introduce the first ship on the U.S. Great Lakes with electric-motive diesel (EMD) engines that generate up to 8,000 horsepower. The twin engines meet the Environmental Protection Agency (EPA) Tier 4 emissions standards requiring particulate matter and NOx emissions to be reduced by approximately 90%. The installation of selective catalytic reduction technology also acts to further reduce the NOx emissions to near-zero levels in the new engines.

Main engine power is directed to a single four-blade, controllable-pitch propeller through a twin-input, single-output gearbox for maximum efficiency. The bow and stern thrusters generate up to 1,000 horsepower, while the high-lift rudder optimizes the propeller’s wake.

The Mark W. Barker is the first new vessel built by Interlake since 1981.

“We’re blessed with fresh water in the Great Lakes, so our vessels do last a long time and operate efficiently with the proper modernization,” Barker says. Since 2006, Interlake has significantly upgraded its existing fleet of nine vessels with newer engines, automation systems, and air exhaust gas cleaning systems.

New prospects

Various factors led to Interlake deciding in 2017 that a new vessel would best meet the needs of both longstanding and new customers. A shortage of truck drivers, highway congestion, limited railcar availability at times, as well as the greater priority now placed by companies on greening their supply chain, are combining to prompt more companies to look at shipping on the Great Lakes.

“We’re having conversations about moving new goods on the water that wouldn’t have ever been considered for maritime transport a few years ago,” Barker says. “Some of this is already happening with us loading U.S. steel for transport on water for the first time ever this fall.”

Barker says the new vessel reflects Interlake’s commitment to Great Lakes trade as the world needs to increasingly move towards greener modes of transportation.

___________________

READ MORE ON THIS TOPIC:

Canada’s leading ship owners invest significantly in fleet renewal to maximize efficiencies