Tug operators invest in engine upgrades and other sustainability efforts

LeadershipGreen Marine’s certified tug and tug-and-barge operators continually work towards minimizing their environmental footprint with newer equipment, cleaner power sources, as well as innovative collaborations. Here are some of the initiatives by Green Marine’s tug and tug-and-barge participants Arrow Launch Service, Atlantic Towing, Marine Towing of Tampa, and Ocean Group, which is also celebrating a half-century in business this year. Happy 50th, Ocean Group!

Arrow Launch Service

Arrow Launch Service has reduced air emissions by modifying its water taxi fleet to eliminate any reliance on diesel generators and use shore power when at the dock in the Puget Sound and Grays Harbor regions of Washington State.

Owned and operated by Jack and Terri Harmon since 1989, Arrow Launch Service is a true family business but also a state-regulated public utility serving the ports of Bellingham, Anacortes, Everett, Seattle, Tacoma, and Port Angeles.

Five years ago, Arrow qualified for the Puget Sound Clean Air Agency’s funding for new generators but ultimately turned it down. “We knew we could do better, so we set out to standardize our vessels so they wouldn’t need to run a generator while in port,” Jack Harmon, Arrow’s president, explains. “We’ve managed to do it on all but one of our 13 boats and we’re still working on changing how the steering is powered on that one.”

To avoid the need for a generator, Arrow installed more efficient LED lighting and DC- rather than AC- powered heaters on the other vessels. “Now the heat from the existing main engines is captured to warm the boats during winter,” Harmon says.

Arrow surveyed the shore-power facilities at all the ports and marinas where it operates to determine the most common plug-in system. “We then standardized our vessels to this model but also figured out with the help of an incredibly smart electrician what we needed in terms of adapters for the other existing systems,” Harmon adds.

Now any of our vessels can use shore power at any of the locations we serve

With its sights on zero carbon emissions, Arrow has been working with naval architects to find batteries sufficiently powerful to run the boats without being so heavy that they compromise the 15- to 18-knots the vessels travel. “We thought we had worked this out, but we’re not there yet,” Harmon shares.

The other issue is that none of the served locations currently have the capabilities necessary for charging about 14,000 pounds (6,350 kilograms) of lithium-ion batteries. “We’re talking with ports and marinas about coming up with a standardized approach because eventually we all want other commercial users and recreational boaters to use shore power, too,” Harmon adds.

In the meantime, Arrow is seeking funds to retrofit its fleet with Tier 3 engines. “Until we can work out the battery power issues, these cleaner engines make the most sense,” Harmon says. “So, we’ve been talking to state legislators about implementing something like the Carl Moyer Program that provides grants for cleaner-than-required engines, equipment and other sources of air pollution in California.”

Atlantic Towing

Atlantic Towing has reduced fuel consumption, air emissions and maintenance costs by installing a hybrid battery system aboard its platform supply vessel (PSV), the Atlantic Shrike.

The hybrid battery system integrated with the PSV’s diesel-electric propulsion system is delivering even better efficiencies than originally anticipated.

“We started out with precise data of how this system could save fuel in our existing operations, but our crews have since discovered opportunities to take better advantage of battery power in our operations, further adding to our fuel savings and emissions reduction,” says Dan Vyselaar, Atlantic Towing’s director of Technology and Development.

Our all-electric mode was originally intended for port operations or shorter transits, but our crews have found we can often use it in calm weather standby operations

Further possibilities exist with the company still collecting data from the new diesel-electric propulsion system that was installed by Vard Electro Canada, a Green Marine partner, last year during a major retrofitting project.

According to Vard Electro, Atlantic Towing was the first company to install this multiple mode battery on a vessel within the Canadian offshore oil and gas sector. The Natural Resources Canada’s Emission Reduction Fund, administered by Energy Research & Innovation Newfoundland and Labrador (ERINL), provided the retrofit project’s investment funding.

Once testing of the battery system is completed, Atlantic Towing plans to begin trials of alternative fuels, including biofuels and possibly renewable diesel.

Atlantic Towing has also been active in training all crew members in identifying whales in the Arctic, Atlantic and Pacific coastal waters where its vessels regularly operate.

“We’ve been working with the Marine Mammal Observation Network so our crews are familiar with the details of each whale species and can more accurately report sightings,” Vyselaar says.

Marine Towing of Tampa

Marine Towing of Tampa has made significant strides in reducing its environmental impact by implementing biofuel in its fleet of four tugboats since May 2023.

The switch to B20 biodiesel has delivered impressive results. “We do not have all of the data fully analysed yet, but there is generally a 17% reduction in emissions with a B20 fuel,” reports Lawrence LeDuc, the company’s manager of Safety, Compliance and Sustainability.

Achieving its initial Green Marine certification earlier this year, Marine Towing of Tampa has embraced the program to benchmark its environmental performance before embarking on further improvements.

“We already had some things in place through our ISM certification, but for some indicators, such as underwater noise, we had to get creative about new policies and practices,” Leduc explains.

In addition to regular hull and propeller cleaning in dry dock, we have adapted our schedules so that our boats can slow down a little so they cause less vibrational noise

Its proactive approach extends beyond noise pollution. Five years ago, each of the four tugs received Certificates of Inspections (COI’s) to comply with the Subchapter M towing vessel regulations. Recognizing that these regulations would come into effect, Marine Towing of Tamp took proactive steps in terms of maintenance, updates, documentation and crew training well in advance to meet the safety and environmental procedures and standards.

To effectively benchmark air emissions, the company uses a database with the U.S. Environmental Protection Agency’s calculations for different fuels. Marine Towing of Tampa also invested in an exhaust gas analyzer to study the impact of biodiesel on emissions. “Once we had our current diesel baseline, we started trying out the B20 fuel to find out how well our engines performed with it and how much of a difference it made in reducing emissions,” LeDuc says.

Emissions from the company’s vehicles, buildings, as well as employee commuting, are all tracked with the goal of reducing them when possible. “We have already switched to all LED lighting to save energy,” LeDuc notes.

For waste management, Marine Towing of Tampa collaborates with a local waste management service to pick up the segregated glass, metal and plastic from different bins on site and take each to a proper recycling facility. All computer and electronic components are documented upon pickup before they go to a recycling depot. Spent oil is likewise recycled.

The company is furthermore encouraging shippers to use less packaging whenever possible. Existing cardboard is picked up by the City of Tampa to help with the burning of brown waste without the help of chemicals.

LeDuc also shared his enthusiasm for exploring innovative solutions during Green Marine’s GreenTech conference last June, when he learned more about the potential of e-methanol and e-ammonia.

Ocean Group

Ocean Group has invested significantly in upgrading its fleet in recent years and subsequently adding new tugs with highly efficient Tier 3 engines. A new addition this past year has been the Ocean Cypress built by Damen, which is now one of the nine tugs in service in and around the Port of Vancouver and the Fraser River area in British Columbia.

Photo: groupocean.com

“We’ve installed equipment on some of our tugs in Quebec to determine their optimal speed for maximizing fuel efficiency and minimizing carbon emissions,” adds Frédéric Maloney, Ocean Group’s executive director of Health, Safety and Environment. “While it varies depending on each tug model, the fuel and emissions savings are in the range of 10%.”

Ocean Group has researched and tested biofuels on its fleet in recent years. “It works extremely well with no mechanical issues at all,” Maloney shares.

The challenge is still obtaining a sufficient regular amount at a feasible cost, as the supply chain for it is still very limited in Quebec, for example, and just totally unavailable in some regions

The company is investigating electric/battery upgrades to its fleet. “We still have some concerns about power capabilities, battery sizes and weights, as well as the necessary shoreside infrastructure and hydroelectric supply, but all of this is evolving quickly in what looks to be a positive direction,” Maloney says.

Celebrating its 50th anniversary, Ocean Group always takes its social license into serious account. When the company expanded its operations to the Port of Vancouver and Fraser River on British Columbia’s West Coast three years ago, management promptly started a dialogue with the local Musqueam First Nations community.

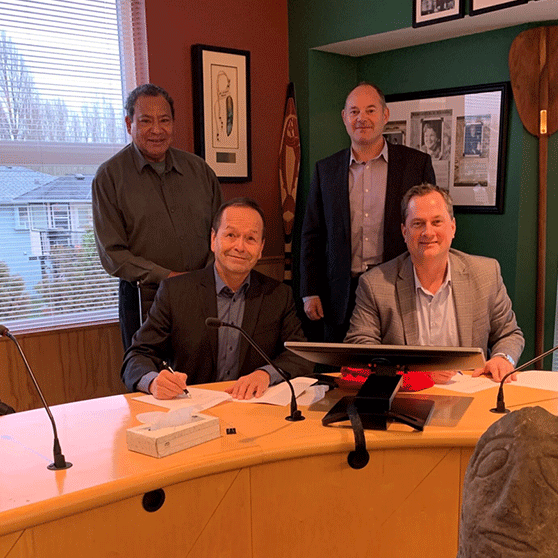

These discussions led to the Musqueam community and Ocean Group signing an agreement earlier this year to collaborate. The agreement prioritizes economic and social benefits for the Musqueam community in the process of establishing contract opportunities with the company.

“Our first initiative involved five members of Musqueam community who were interested in a marine career successfully completing their bridge watch training at the British Columbia Institute of Technology (BCIT) Marine Campus and then doing an onboard internship that will lead to hiring by Ocean Group,” Philippe Filion, director of Corporate and Public Affairs, says. “We’re now identifying other potential candidates, which is so great at a time when our industry is short supply of new good mariners.”

Ocean Group has also just signed an agreement to obtain renewable liquid natural gas in due course from Nation Clean Energy Inc., another Musqueam business partner.

“These initiatives are just the start of what we hope will be various forms of collaboration in the years ahead,” Filion adds.

Ocean is not just doing one or two projects and saying it’s done its part, but instead really committing to working long term together

Ocean is also using three of its latest generation tugs to provide towing, escort and salvage services to the Jamaican Port Authority at the Port of Kingston. “We recently extended the original contract signed in 2018 by five years for this increasingly busy Caribbean trade hub,” confirms Filion.

He praised the high level of training achieved by the 30 local employees hired by Ocean Group for responding expertly when recently a gas leak at the port required an emergency response by the tugs to secure the affected port area. “Everyone is always keen to learn new skills, which is great,” Filion says.