CSL Australia plans shore power to reduce CO2 emissions

DecarbonizationCSL Australia partners to plan shore power that will significantly reduce carbon emissions.

Since its 1999 establishment, CSL Australia Ltd. (CSLA), a division of the Canadian-based CSL Group (CSL), has become the biggest owner/operator of dry bulk coastal vessels in Australian waters and a leading provider of shipping services to the construction and building industries. Based in Sydney, the Australian operations consist of a fleet of three self-unloading ships, five pneumatic cement carriers, two bulk carriers, four transshipment vessels and two barges.

CSLA also holds the designation of being the first shipping operation in Australia to participate in Green Marine after joining the program in 2012, as part CSL’s international participant group.

“Canada Steamship Lines, the company’s Great Lakes business, is a proud founding member of Green Marine in Canada, so our commitment to the program in Australia was essential to ensuring a consistent approach to sustainability across our global operations and to set clear targets for our sustainability efforts,” says Emily Pointon, CSL’s global ESG director.

Renewable shore power

“Our customers are putting a lot more emphasis on sustainability these days and requesting that we partner with them to identify opportunities to collaboratively reduce emissions across their supply chains,” she adds.

As a result, we have prioritized our pneumatic carriers, recognizing the significant impact shore power can make in reducing their reliance on fossil fuels.

In 2022, CSLA signed a Letter of Intent with the Port Authority of New South Wales and other industry leaders, including one of CSLA’s largest customers, Cement Australia. The goal is to install renewable shore power at the Glebe Island berths in Sydney.

“We have a pneumatic carrier transporting cement or a ship delivering gypsum to this location once a week, so our frequent call status made this a good case for using shore power,” Pointon explains. "This is especially true for pneumatic cement carriers, as they consume significantly more fuel during portside operations compared to bulk carriers, with daily consumption ranging from 10 to 12 tonnes for transferring powdered cement ashore."

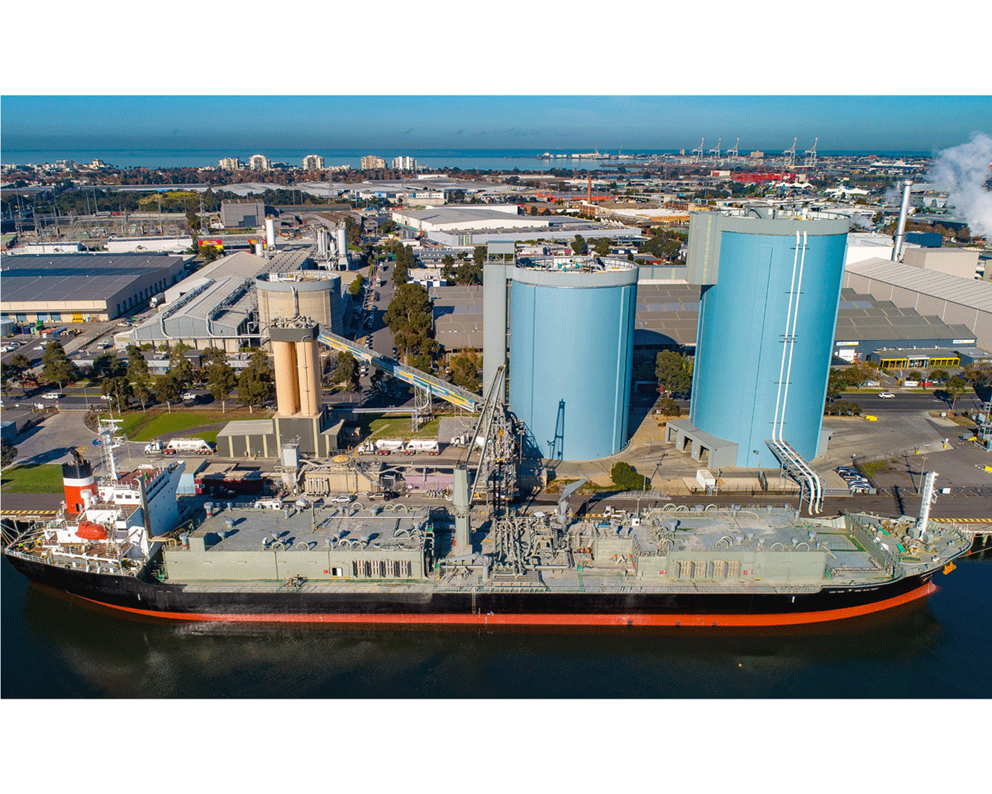

The company has also launched preliminary discussions with the Port of Melbourne in the hopes of having plug-in power installed there in the future.

We’re at the very early stages of together looking at the feasibility of a shore power installation alongside the cement silos.

"By leveraging our learnings and design expertise from our Sydney operations, we can also effectively utilize the equipment installed on the vessels in Melbourne without any additional investment," she adds. “This would substantially increase the project’s economic viability and potential emissions reduction.”

Cleaner air would be a big plus for the many residential areas that now surround Glebe Island in Sydney. Shore power would also reduce noise significantly. “It would help to keep Sydney Harbour as a working port in harmony with the community, which from a business and supply chain standpoint is important to maintain,” Pointon notes.

The pneumatic carriers will be retrofitted for plug-in power when they are next scheduled for drydocking, starting with Kondili, then Akuna and Wyuna. “We’re aiming to have all three ships ready to receive shore power when the project comes online at Glebe Island by December 2024,” Pointon shares.

Biofuel initiative

Following the CSL Group’s highly successful trials of B-100 biodiesel fuels on several Canadian vessels since 2019, CSLA plans to conduct its own pilot project with a B-20 blend this year.

“Our technical team is confident that the B-20 blend will be successful as a drop-in fuel for a short trial period,” Pointon shares. “Making a long-term commitment to obtaining a continuous supply of up to a B-100 fuel is difficult at this point because of the high cost and the limited availability with most biodiesel feedstock currently being exported from Australia.

“We hope to build support for increased production of marine biofuel in Australia, recognizing its significance as an interim solution in the shift towards cleaner fuel sources,” she adds. “We strongly encourage favourable policy measures, grants, or subsidies to promote its use in marine applications, similar to the support we’ve seen for land-based transportation.”

To maximize vessel efficiencies, CSLA operates the CSL-developed Operational Optimizer (O2) energy management system aboard all its vessels. “The ability of a ship’s crew to respond to real-time data is allowing us to really start getting into granular efficiency improvements that add up to fuel cost and emission reduction over time,” Pointon notes.

The O2 system complements other technical improvements that are gradually being installed across the fleet, including engine power limitation devices that restrict the power the main engine can use, and propeller boss cap fins that reduce the amount of energy required for a vessel to maintain a given speed.

Battery exploration

CSLA is also looking into the feasibility of battery-powered vessels for shortsea trading routes. “Electrification is best suited to our trades where sea transits are only six to 10 hours between ports and where renewable shore power would be available alongside our vessels,” Pointon says.

Bottlenose dolphins commonly inhabit the southern Australian ports frequently visited by CSLA vessels and battery solutions would make life quieter for these marine mammals.

CSLA currently partners with Dolphin Research Institute which monitors dolphin activity in Port Phillip Bay, and many CSL vessels also regularly play host to the local seal population.

This content is not available because some cookies are blocked.

By clicking on this link, you agree that Youtube may collect data about you for targeting purposes. The video content will be displayed.

___________________

AUSTRALIA SPOTLIGHT - READ MORE ON THIS TOPIC:

Spirit of Tasmania becomes the first Australian ferry service to participate in Green Marine